Lets make a Squirrel Cooker

I will list step by step procedures to make a squirrel cooker. This project is a beginer project with the basic already learned. You will need to know how to tapper, twist and flatten.

|

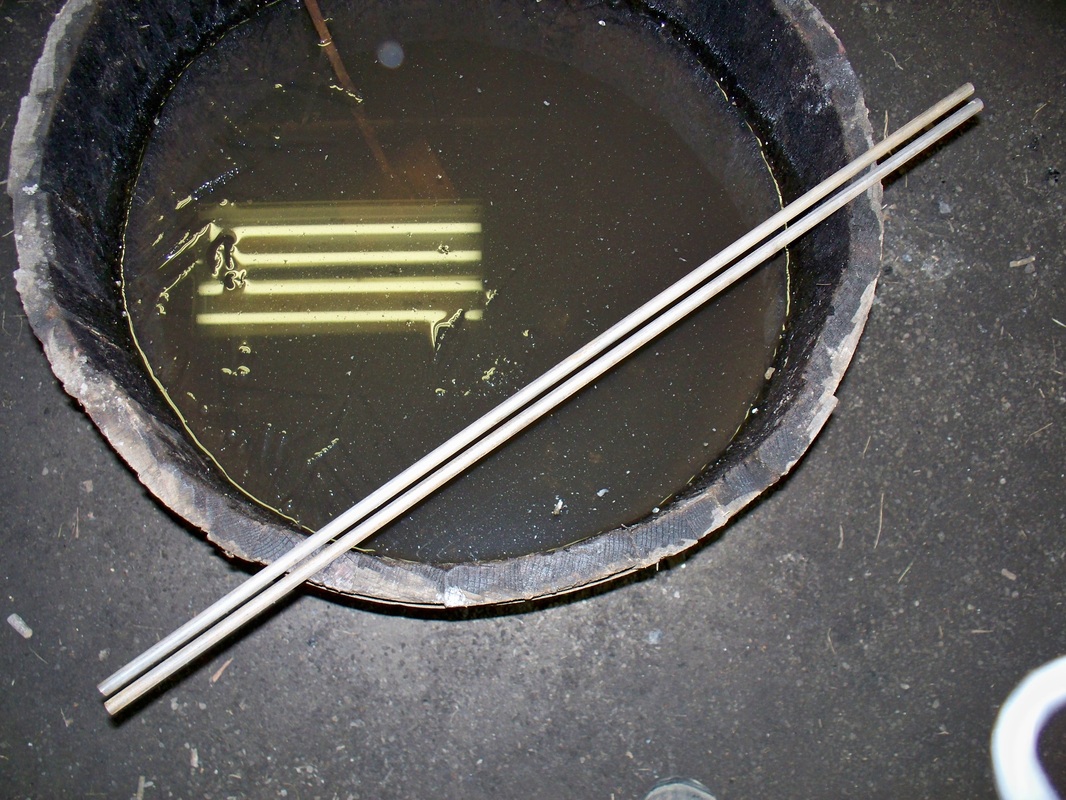

1. Cut 2x lengths 30" of 3/8" hot rolled round stock.

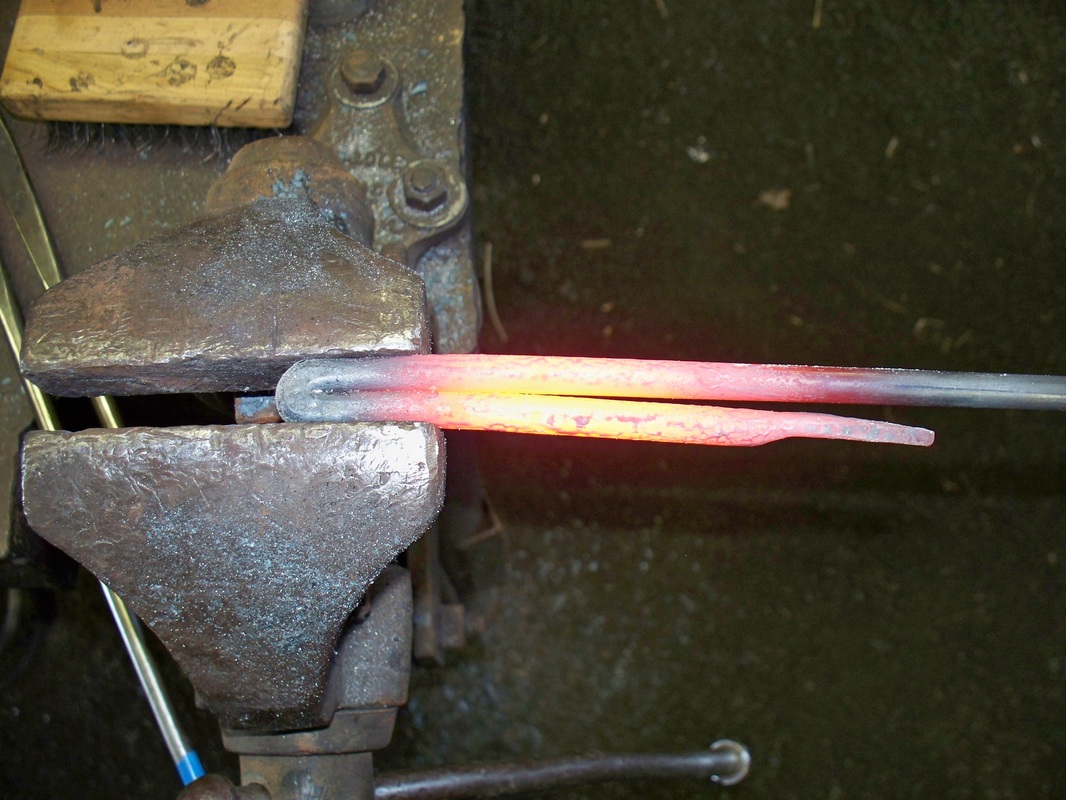

3. Grab the second Rod and hammer a spade point on it.

5. On the same end you just flattened fold it over about 7" down the rod.

|

2. Hammer 2-3" flat area on the end. Twice as wide as thick. Set aside to cool slowly

4. Hammer a 1 1/2" - 2" fat spot on the other end of the rod.

6. Clamp 1 1/2" into the vise.

|

7. Take your tongs grab the end you flattened just at the transition and lead it around in a loop. When finished the flat tab should be perpendicular to the main shaft with about a 1/2- 3/4 inch space. You may want to test the loop to make sure it holds the fork straight. Tightening or loosening the loop will determine how the rod is held.

|

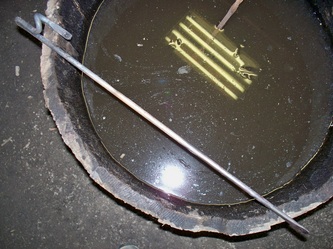

8. Time to return to the first rod. It will have cooled by now and will be abit annealed. This will make it easier to saw. Saw down the center of the flattened area. It is most important to end in the center. You can trim or lengthen the tines but if you stop off center it will never look quite right.

Small tip, if you put your thumb nail at the point where you want to start sawing and draw back guided against your nail it will start faster. |

|

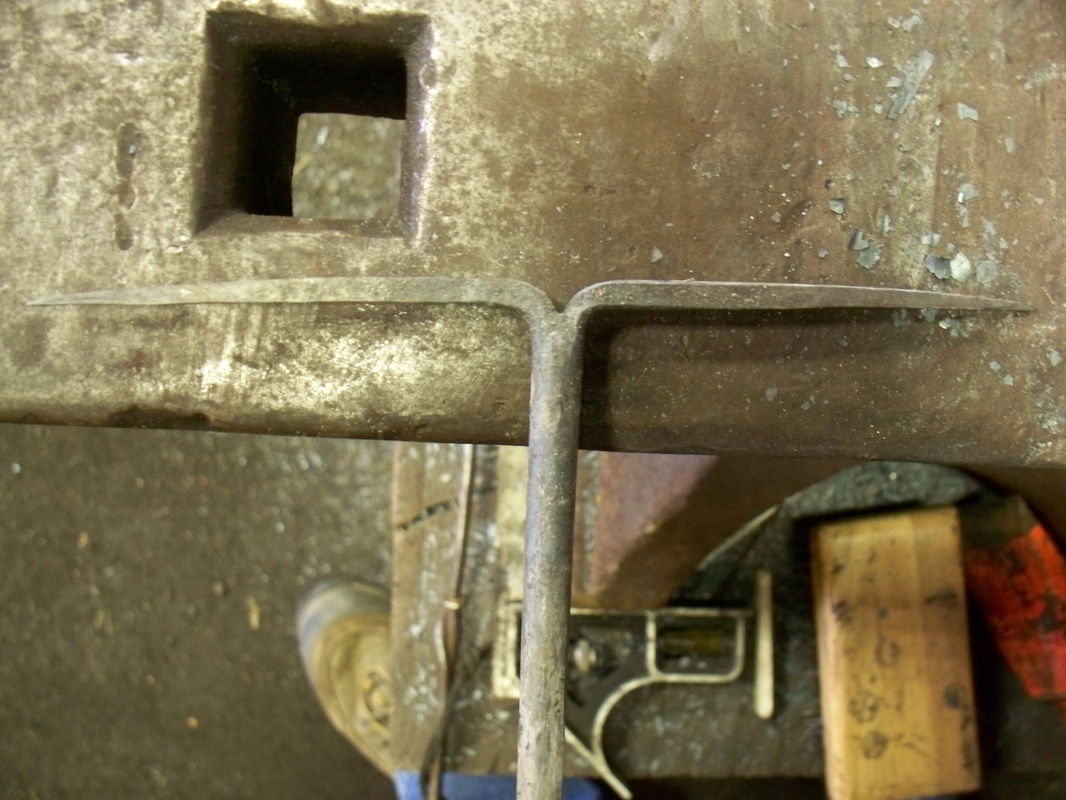

9. Use a cut off hardie or a chisle to spread your cut to a Y shape..

11. Shape one tine at a time. When 1 tine is tappered to your pleasing mark the length on the anvil.

|

10. Then put your rod over the edge of the anvil and use your hammer to turn your Y to a T.

12. When the second tine matches the length of the first you are ready to shape your fork.

|

Tapper the other end of the fork. Then curl a small loop. Cool the loop and hammer on it to form a hook as shown.

Flatten an area for the handle from the hook forward about 5". Twist handle as you find pleasing. When twisting the handle try clamping below the flattened area. Heat the area flattened and beyond and twist. This will allow the twist to tapper into the non flattened area. That will finish this project. Some minor details I like to do. I put the fork 90 degrees off from the hook. I also like to to put the spade tip 90 degrees off from the mounted fork.